Weiss Technik is introducing a modular system for two-part high-performance climatic test systems. This enables faster and more cost-effective delivery of units which were previously custom-made. However, special requests can still be made for test systems for electric vehicle drives.

With a newly designed modular construction, Weiss Technik is responding to the increasing demand for test systems for electric motors and electric axles, gearboxes and inverters. With their high cooling capacities, these climate units cope with the intense heat generated during electric drive tests. Until now, these units were custom-made to order.

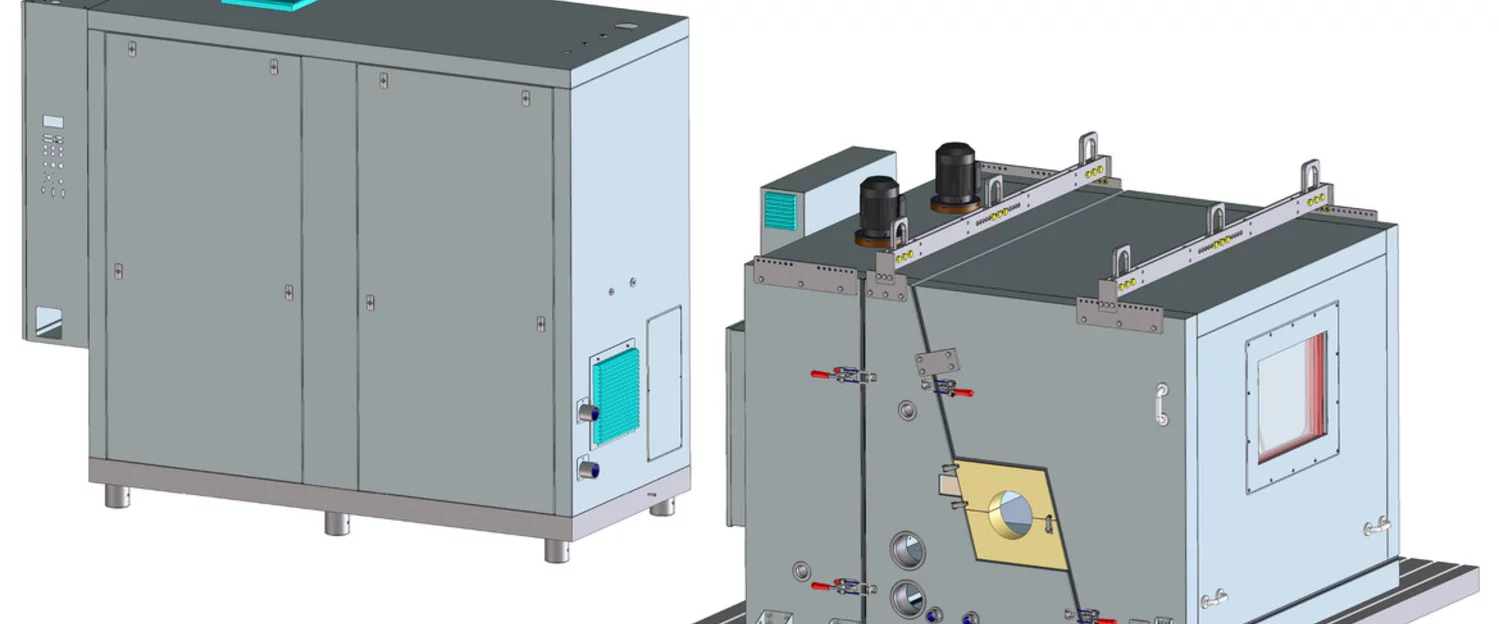

The new system allows assembly to take place from pre-produced components, which saves time and costs on a large scale. The test systems are called MURs (Machine Unit Remotes) because their high performance allows the cooling/heating unit (machine unit) to be placed up to 15 m horizontally and 4 m vertically away from the test chamber.

The modular system comprises five differently powerful machine units for climate control, three preliminary stages for conditioning the test air as well as test chambers in five sizes. In total, this results in 75 different unit configurations. In addition, Weiss Technik continues to carry out customisations according to customer specifications. The MURs from Weiss Technik are available with test chambers up to a volume of 5 m3. The cooling capacities of the standardised machine units range up to 21 kW. All these simplifications mean that the supply period is now only a few days. Previously, deciding on the constructional details often took weeks. Delivery time is now also significantly shorter.