Weiss Technik Nederland B.V.

Newtonstraat 5, 4004 KD Tiel, Nederland

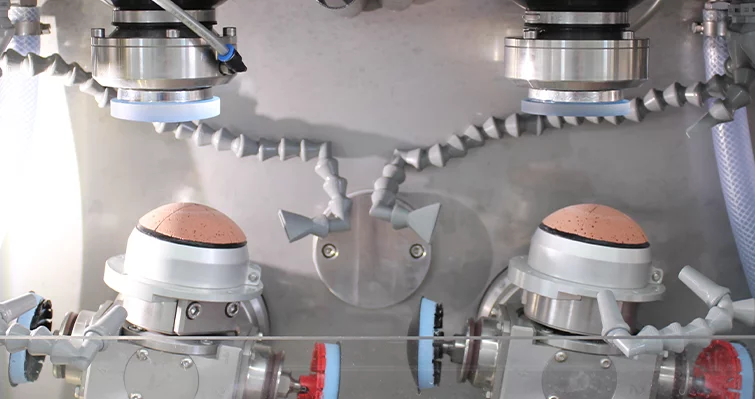

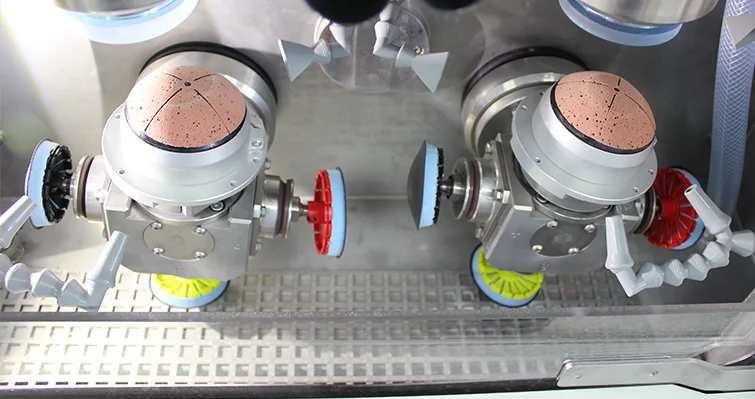

The OptoTech Easy Twin CNC is a low cost two-spindle polishing machine for fine polishing of ophthalmic lenses with progressive, custom made, spherical, a-toric, toric, convex and concave surface geometries.

Contact request

Polishing Tank, Polishing Tools, Chiller

Newtonstraat 5, 4004 KD Tiel, Nederland