Weiss Technik Nederland B.V.

Newtonstraat 5, 4004 KD Tiel, Nederland

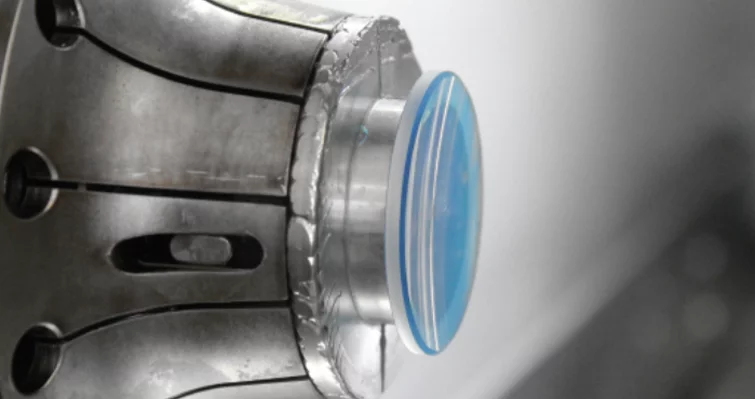

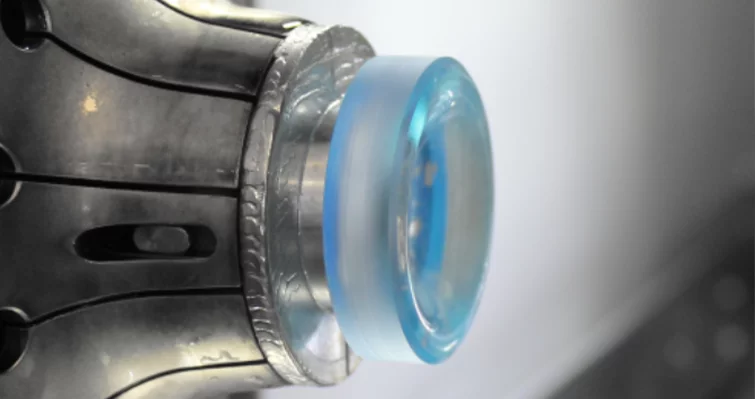

The FLASH-A NG is the most recent member of our FLASH series. Considerably increased speed of the workpiece spindle, combined with an optimized Fast-Tool and a new designed auto loader, leads to significant improvements in quality and quantity. The combination of an optimized ultrafast tool spindle and a high-performance controller make the FLASH-A NG one of the most efficient digital surfacing-turning machines on the market.

Contact request

Newtonstraat 5, 4004 KD Tiel, Nederland