Weiss Technik Nederland B.V.

Newtonstraat 5, 4004 KD Tiel, Nederland

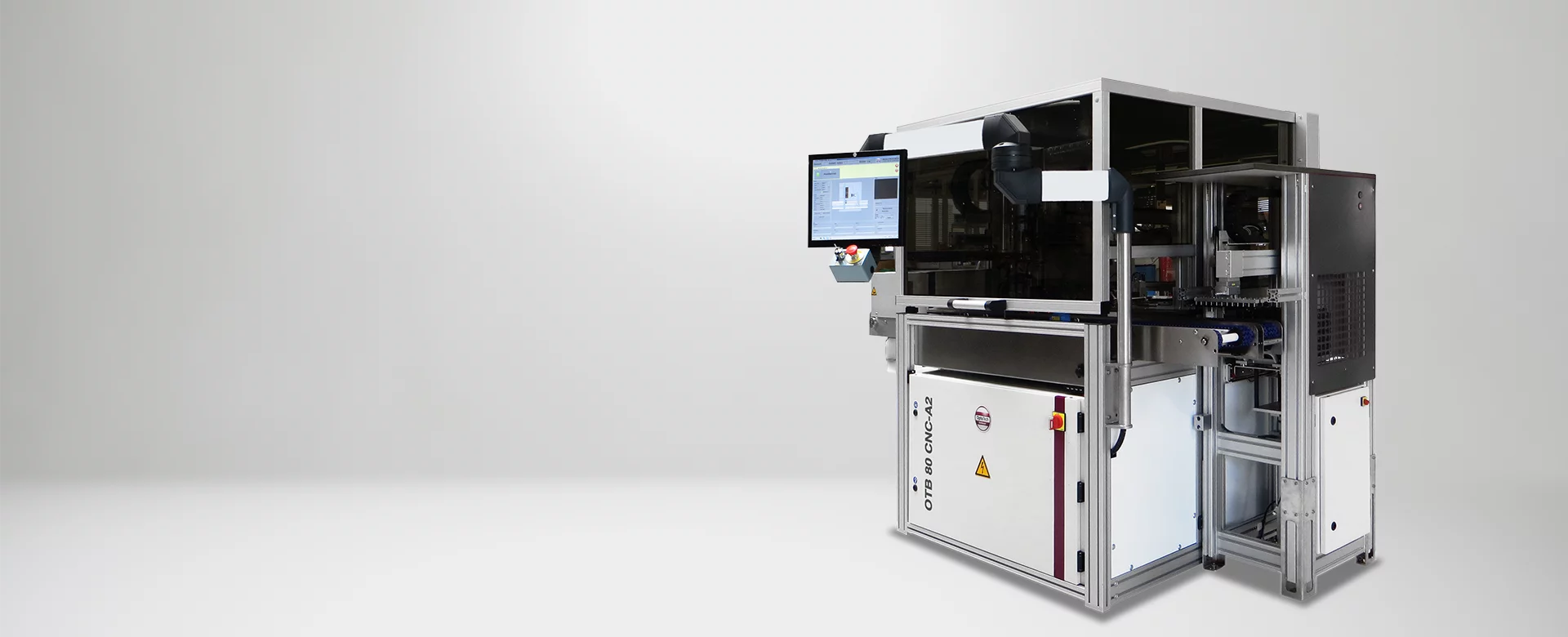

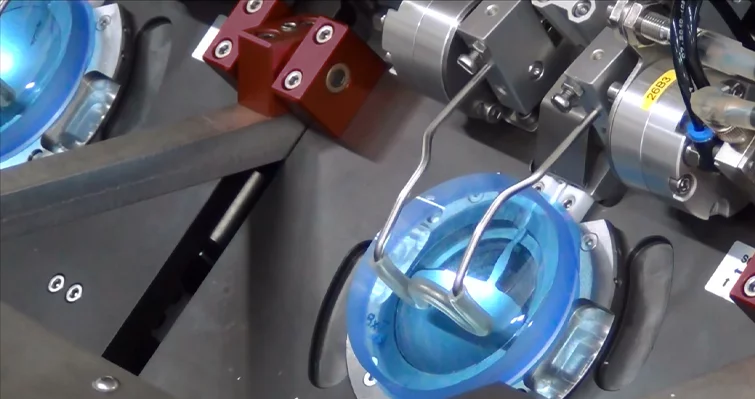

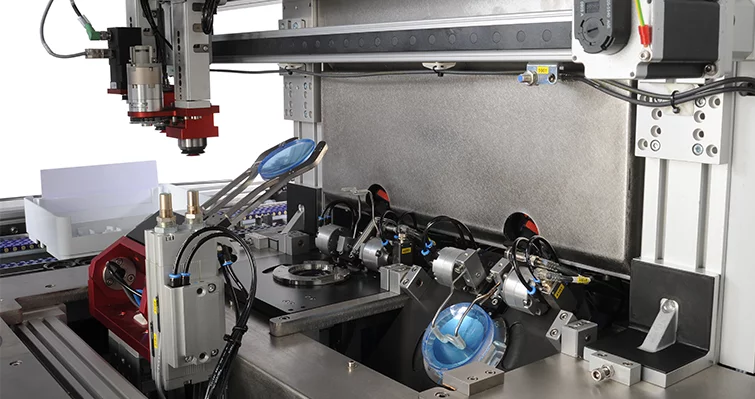

The 2-station auto blocker OTB 80 CNC-A2 is the ideal alloy blocker for midsize and big laboratories.

Contact request

Blocking Rings, Blocking Chucks, Measurement Devices, Different Alloy, Chiller, Cooling Plate, De-Blocking Rings of Various Diameter, De-Blocking Tank; Blockpiece Stacker

Newtonstraat 5, 4004 KD Tiel, Nederland